| Send a message |

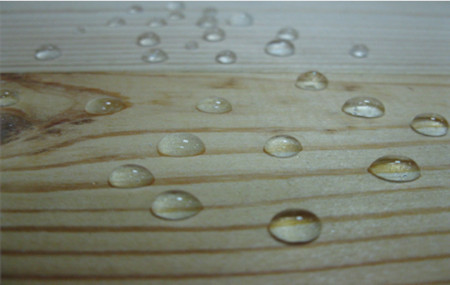

penetrating water repellents

based on nanotechnology

| HOW IT WORKS? (ru) |

| ADVANTAGES OF TECHNOLOGY (ru) |

| AREAS OF USE (ru) |

| VIDEO MATERIAL (ru) |

| REPRESENTATIVES IN REGIONS (ru) |

| OUR CONTACTS (ru) |

| Documents for download |

| Contact phone numbers |

| Russia | +7 (919) 786-65-53 |

| Belarus | +375 (29) 618-08-95 |

| Fax | +375 (163) 66-87-32 |

|

Modern ways of wood durability increasing is a complex task. Wood belongs to the group of combustible, biodestructive building materials and to increase the durability of buildings and structures are needed not only fire retardant materials, but also antiseptics and fungicides,which able to protect against bio-corrosion. Fire protection of wooden building structures includes: wood impregnation with flame retardants; surface coating with fire retardant paints; coating with fire-retardant pastes; surface coating fire-retardant plaster solutions. The list of such substances has decreased dramatically due to increased requirements of European standards for protective compositions. On the other hand, wood, which consists mainly of cellulose, is a nutritional substance for many micro and macro-organisms causing biological corrosion. The main role in the decomposition of cellulose is played by fungus. A large group of wood-destroying fungi are involved in the decomposition of cellulose inlaid with lignin (wood), causing wood rot, characterized by dark color, rottenness and the ability to easily crumble to powder. Wood-destroying fungi have the highest growth rate with an absolute humidity of wood of 30-80%. It is significant that in case of some fungi, especially mold, even a small decrease in humidity delays the formation of spores. It is also important to protect the wood from the attack of insect larvae - technical pests. Currently, there are a number of fire retardants and antiseptics in global market, that can reliably protect the wood from fire and biodegradation. However, due to the fact that the substances, the solutions of which are used for impregnation of wood, must be well soluble in water, they also dissolve wellunder the action of precipitation on the impregnated wood. As a result, flame retardants and antiseptics are washed out of wood, and wood loses its fire and bioprotective properties. To prevent the washing out of lame retardants and antiseptics, a series of water repellents “HYDROEFFECT” has been developed, which, after treatment the surface of wood, prevent water from entering the wood pores and leaching of substances. Water repellents are available not only on an organic solvent, but also in the form of a finely divided water-based emulsion. Depending on the purpose in one case, the treatment with water repellents of wood, pre-impregnated with fire retardants and antiseptics preserves the texture, doesn’t prevent breathing, doesn’t allow drip water. In addition, the surface is covered with a thin hydrophobic film that allows you to completely close the pores Hydrophobic coatings "HYDROEFFECT" are non-flammable, non-toxic, don’t contain heavy metals and chlorine, resistant to UV radiation. Surface treatment of wood by products "HYDROEFECT" can be carried out without prior impregnation with flame retardants and antiseptics, which will also significantly increase the service life of wood due to the lack of moisture in the pores, contributing to the development of micro-and microorganisms. Water repellents with organic solvents are recommended to be used outdoors or in well-ventilated areas, while on a water basis - indoors. Staining water repellents with regard to the pH of the solution in various colors opens up the possibility of decorative wood finishing and, at the same time, receive the color palette of various colored wood species.

Thus, depending on the purpose and the appropriate level of protection, wood processing involves various technologies: Wood processing with water repellents "HYDROEFFEKT"; Wood impregnation with flameretardant and then with water repellent; Wood impregnation with antiseptic, glameretardant, and then treatment with water repellent; Wood treatment with a single agent with flame-retardant and fungicidal properties, and then with water repellent; The durability of the wood will depend on compliance with the instructions and the conditions of the phased wood processing. |

|

|

© 2015 :: «TD NANOGIDROKOM» Ltd. :: Republic of Belarus :: Baranovichi

|